Chennai

𝟗𝟖𝟖𝟒𝟓 𝟓𝟖𝟖𝟗𝟑 / 𝟗𝟖𝟖𝟒𝟐 𝟒𝟏𝟗𝟓𝟎

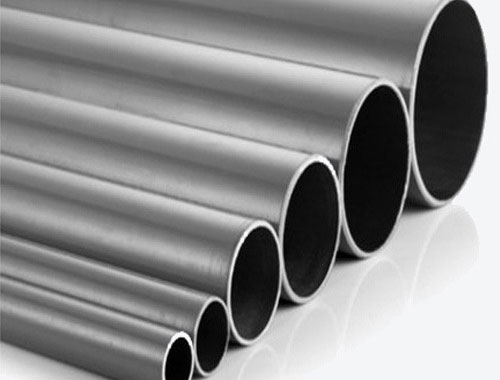

Aluminum tubing is a machined component commonly used in all types of industrial projects where light weight and corrosion resistance are important. Types of aluminium pipes include -6061-T6 and 6063-T6, 6063. 6061 has a smoother texture than other types and is more bendable.

Manufacturers of aerospace, automobiles and rail transport use aluminum tubes for their fuselage, hydraulic systems and fuel lines, and their thermal conductivity makes them an excellent alternative to steel and other heavy metals in refrigerators, engines and HVAC systems.

The corrosion resistance of aluminum tubing means optimal air flow, reduced energy costs, and improved air quality. The fittings used in aluminum pipe systems are safe and have much less leakage than the fittings used in threaded systems. This directly leads to energy savings and increased plant productivity.

Product Description

Our aluminum tubing is available in different dimensions to facilitate use in different industries. These are corrosion and heat resistant bars used in the manufacture of different devices in different industries. We are built on the skills of our experienced team of professionals and are committed to providing high quality aluminum tubing.

We have a proven track record of offering a wide range of aluminium pipes at very competitive prices that feature rugged construction, durable finishes, perfect dimensions, heat resistance, wear resistance, weather resistance, and more. Because of our high-quality products and on-time delivery, Metal & Alloy Industries has gained an impeccable reputation in the market.